SERVICES

ESD Antistatic Flooring Service in California

Electrostatic Discharge (ESD) epoxy flooring is a cutting-edge solution designed to safeguard delicate electronics from potential damage caused by static electricity. With static electricity accumulating as people walk, our ESD epoxy flooring offers a reliable and effective defense against this risk.

Our ESD flooring is formulated with conductive elements, such as carbon, graphite, or metal-coated particles, that are evenly dispersed throughout the epoxy material. These elements provide the flooring with exceptional electrical conductivity, creating a designated pathway for static electricity to safely dissipate to the ground, ensuring optimal protection for sensitive electronics.

We have two primary of flooring to reduce or dissipate static electricity:

- Electrostatic discharge (ESD) Flooring

- Anti Static Flooring

GET NOW A FREE QUOTE

Fill this form below and we will get back to you as soon as possible

Uses

ESD (Electrostatic Discharge) epoxy flooring is designed to disperse static electricity and is commonly used in electronic manufacturing facilities to protect delicate electronic components. It is created by combining a conductive substance, such as carbon, with epoxy resin, which is then applied to the floor and left to cure. Once cured, the flooring becomes electrically conductive and dissipates static charge.

ESD epoxy flooring finds application in various sectors, including semiconductor, electronics, computer, and healthcare industries. It plays a critical role in safeguarding electronic equipment.

On the other hand, antistatic flooring is designed to reduce static electricity and is suitable for environments where static buildup is not a significant risk. It typically has chemical coatings that distribute static electricity throughout the floor, preventing charge accumulation that could cause damage to sensitive equipment or result in injury.

The choice between antistatic and ESD flooring depends on the working environment. In some workplaces and industries, static buildup can be dangerous, while in others, it may be a minor inconvenience. Antistatic flooring is suitable when static electricity is not a fundamental risk to the process or working environment, as it prevents the floor from generating static but may not completely eliminate or dissipate static that has built up in the body.

For higher protection against static electricity, ESD flooring is recommended. It is the best option for industries or workplaces that deal with objects or use equipment susceptible to electrostatic discharge, especially in environments where combustible materials are present.

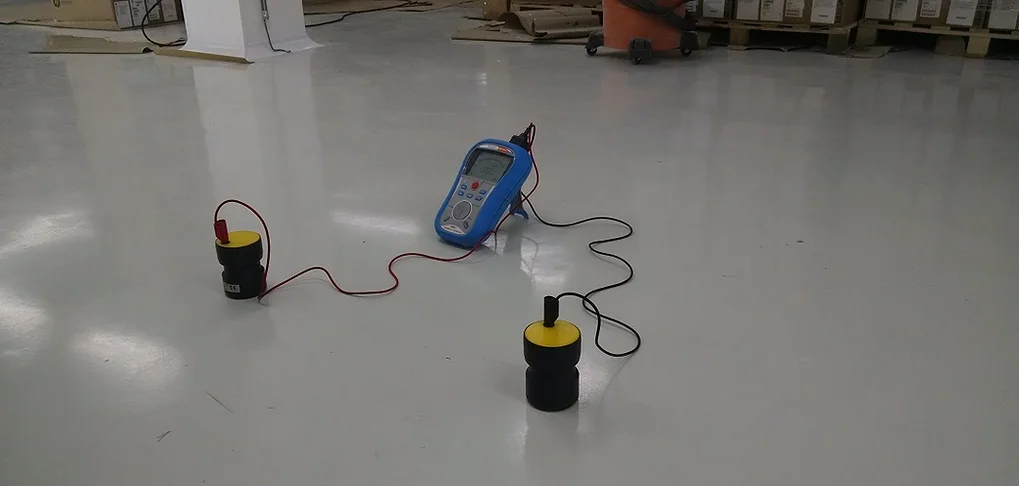

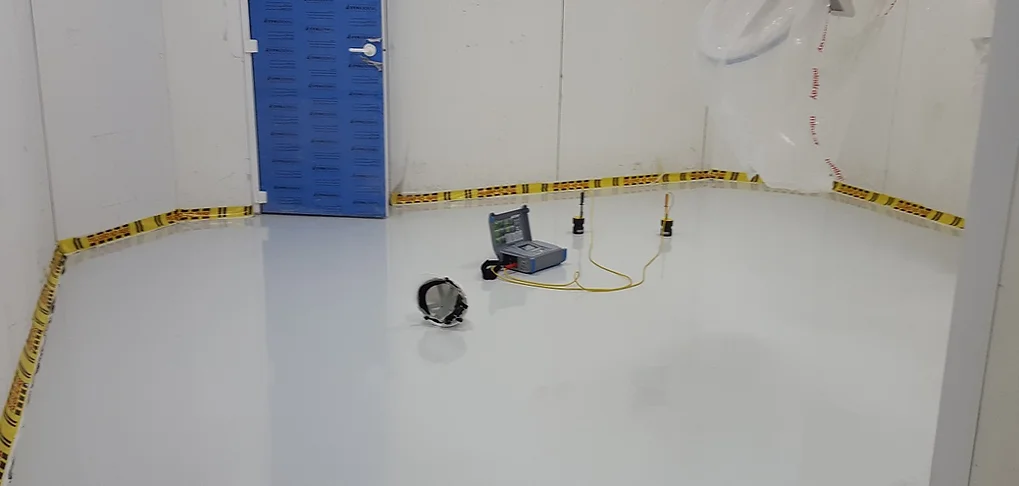

ESD flooring standards are based on a combination of ESD flooring and footwear. Some ESD floors also prevent charge generation, which means they prevent static from accumulating as people walk. Therefore, it is crucial to determine the type of footwear that will be used in the space and test for both electrical resistance (STM7.1) and charge generation (STM97.2-2014) when choosing an ESD floor.

Beneficts

- Reduces the danger of electrostatic discharge (ESD) damage: Antistatic flooring aids in the prevention of static electricity accumulation, which can harm electronic equipment and components.

- Increases safety: In some situations, such as those with dangerous gases or liquids, static electricity can be a safety problem. Static energy can ignite these materials, thus antistatic flooring can help.

- Improves product reliability: Antistatic flooring in manufacturing environments can assist to guarantee that goods are not harmed throughout the manufacturing process owing to static electricity.

- Increases worker comfort: Antistatic flooring can also assist to minimize static shock, which can be uncomfortable for workers who stand or walk for long periods of time on the floor.

- Reduces static cling: Antistatic flooring can also aid in the reduction of static cling, which can be an issue in some situations, such as those containing fabrics or plastics.

Composition

Pre-application System

- Surface Preparation: The initial stage entails grinding or decontaminating the concrete surface as required, ensuring a clean and flawless base for the application of the epoxy flakes system.

- Cracks Treatment: Any cracks in the concrete are addressed using specialized products that effectively repair, fill, and seal them prior to the application of the Epoxy Flakes System, ensuring a seamless and durable finish.

Antistatic Floor:

- Conductive polymers: are polymers containing conductive components like carbon, copper, or silver. To provide the requisite conductivity, conductive polymers are frequently employed in the top layer of antistatic flooring.

- Carbon fibers: Because of their low electrical resistance and conductivity, carbon fibers are a typical material used in antistatic flooring.

- Metal grids: To promote conductivity, certain forms of antistatic flooring feature metal grids or wires embedded in the material.

- Conductive adhesives: Conductive adhesives can be used to attach layers of antistatic flooring together.

- Grounding systems: Grounding systems, in addition to the materials used in the flooring, are frequently added to guarantee that any static charges are properly dissipated away from sensitive equipment or materials.

EDS Flooring

- Fillers: Fillers are used to improve the mechanical qualities of flooring materials such as hardness, durability, and abrasion resistance. Fillers include quartz, calcium carbonate, and aluminum oxide.

- Binders: Binders are used to adhere the flooring material to the substrate and retain the flooring material together. Binders might be epoxy resins, vinyl ester resins, or acrylic polymers.

- Additives are used to change the qualities of a flooring material, such as its flexibility, UV stability, or fire resistance. Plasticizers are an example of an additive.

- Conductive or dissipative materials are used in flooring to offer the necessary amount of electrical conductivity or resistance. Conductive materials include carbon or metal particles, whereas dissipative materials include polymers or rubber.

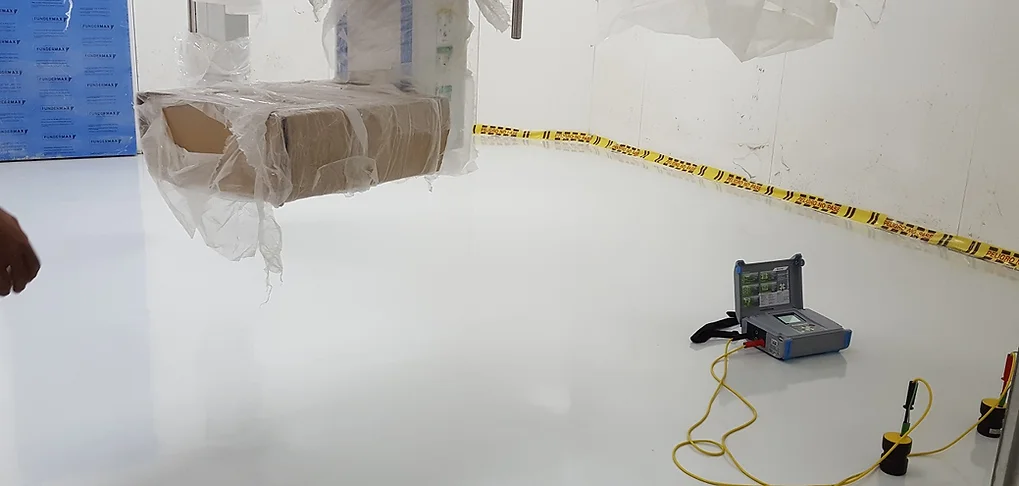

Application method

Regarding the Epoxy anti static flooring installation entails adequate surface preparation, mixing the epoxy coating with conductive additive, and applying the coating with care to obtain the desired thickness and conductivity. When correctly implemented, epoxy antistatic flooring provides a long-lasting and effective solution for static management in a variety of settings.

On the other hand, ESD flooring installation requires adequate subfloor preparation and careful installation of the ESD flooring material. Whether utilizing tiles, sheets, or coatings, it is critical to carefully follow the manufacturer’s recommendations in order to get the appropriate ESD qualities and provide a safe and effective static electricity management solution.