SERVICES

Metallic Flooring Service in California

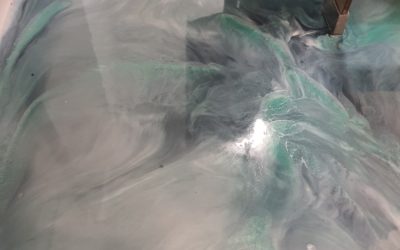

A metallic epoxy system is a cutting-edge flooring material that combines the unmatched durability and functionality of epoxy with the stunning aesthetic appeal of metallic finishes. It has become increasingly popular in commercial, industrial, and residential settings due to its ability to create a mesmerizing and eye-catching appearance.

The metallic pigments used in metallic flooring epoxy systems offer a diverse array of colors, ranging from dazzling silver and opulent gold to rich copper and timeless bronze. These pigments are expertly mixed with the epoxy resin and skillfully applied to the floor in a meticulously crafted pattern or design. The end result is a breathtaking and truly one-of-a-kind flooring system that is guaranteed to captivate and impress anyone who sets eyes on it.

GET NOW A FREE QUOTE

Fill this form below and we will get back to you as soon as possible

Uses

- Show Room

- Offices

- Retail stores

- Restaurants

- Warehouses

- Manufacturing facilities

- Garages

- Livingrooms

- Hotels

- Resorts

- Schools

- Museums

- Galleries

Beneficts

- High durability: Metallic epoxy floors are renowned for their exceptional durability and longevity. They are resistant to stains, chemicals, abrasions, and wear, making them ideal for high-traffic areas and commercial applications.

- Customization Options: Metallic epoxy floors are highly customizable, allowing you to choose from a wide range of colors, patterns, and finishes to suit your design preferences. You can create a truly personalized floor that complements your overall decor and enhances the visual appeal of your space.

- Easy to Clean and Maintain: Metallic epoxy floors are easy to clean and maintain, requiring minimal effort and resources to keep them looking pristine. They are resistant to dirt, dust, and moisture, making them a hygienic choice for environments where cleanliness is a priority, such as kitchens, bathrooms, and healthcare facilities.

- Elegant and unique Style: The unique metallic pigments create a mesmerizing, three-dimensional effect that can mimic the look of polished metal or marbled surfaces, resulting in a stunning and distinctive floor finish.

- Cost-effective: Compared to other flooring options like natural stone or hardwood, metallic epoxy floors offer a cost-effective solution with comparable aesthetics and durability.

Composition

a) Preparation

Proper pre-epoxy system preparation is absolutely critical for the success of an epoxy flakes flooring system. It is imperative that the concrete substrate is thoroughly cleaned, dried, and free of any contaminants prior to applying the epoxy flake coating. This includes removing any dust, dirt, oil, grease, or debris from the concrete surface using vacuum priming, and addressing any cracks or divots with suitable patching materials.

- Surface Preparation: The first step involves grinding or decontaminating the concrete as needed to ensure a pristine surface for the epoxy flakes system.

- Cracks Treatment: Cracks are treated using specialized products to fix, fill, and seal them before proceeding with the application of the Epoxy Flakes System.

b) Epoxy Metallic floor system.

Our metallic epoxy floor system includes the following steps:

- Primer: A primer is applied to the surface to improve adhesion and provide a base for the metallic flooring to bond to, ensuring durability and longevity.

- Base Coat: A base coat of clear epoxy is applied to the surface, creating a smooth and even foundation for the metallic pigments to be applied onto.

- Metallic Pigment Application: The metallic pigments are mixed with the epoxy resin and skillfully applied to the base coat in a specific pattern or design, creating a unique and three-dimensional look.

- Clear Coat: A final clear coat of epoxy is applied over the metallic flooring system to protect the surface and provide a glossy finish that enhances the overall aesthetics of the floor.

Our meticulous process ensures that each step is carefully executed to achieve a stunning and durable metallic epoxy floor that will elevate the beauty and elegance of your space. Contact us now to learn more about our metallic epoxy flooring options and transform your space into a masterpiece.

Application method

The application method of a metallic flooring system involves a meticulous multi-step process that demands careful preparation and attention to detail. Although the specific application steps may vary depending on the manufacturer and product, there are generally common steps involved.

The initial step entails mixing the metallic pigments with the epoxy resin, which is then applied to the base coat in a predetermined pattern or design. The pigments are evenly spread to create a distinct and captivating three-dimensional appearance. The amount of pigment used can be adjusted to achieve the desired effect.

Following the application of the metallic pigments, a final clear coat of epoxy is applied to protect the surface and provide a glossy finish. The curing time for the metallic flooring system may vary depending on the manufacturer and product, typically ranging from 24-72 hours. Maintaining proper temperature and humidity levels during the curing process is crucial for ensuring a proper cure.

Once the metallic floor has cured, it can be easily cleaned and maintained with regular sweeping and mopping. However, it is important to avoid using harsh chemicals or abrasive cleaners, as these can potentially damage the surface of the metallic floor.